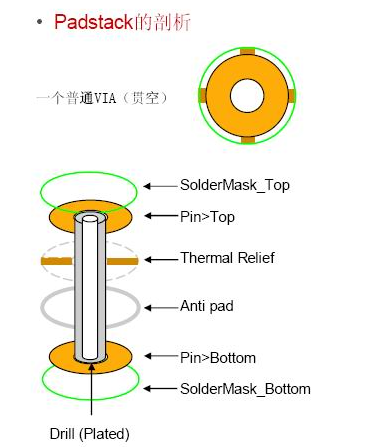

1、焊盘分类及作用

Regular Pad:规则焊盘,在正片中看到的焊盘,也是基本的盘。

Thermal Relief:热风盘,也叫花焊盘,在负片中有效,设计用于在负片中焊盘与敷铜的接连方式,防止焊接时散热太快,影响工艺。

Anti Pad:隔离焊盘,焊盘与敷铜的间距,负片工艺中有效。

Soldermask:阻焊层,规定绿油开窗大小,以便进行焊接。

Pastemask:钢网层,定义钢网开窗大小,贴片的时候会按照钢网的位置和大小,进行锡膏涂敷。

2、贴片类焊盘

1)常规焊盘

Regular Pad = 器件管脚尺寸+补偿值。(补偿值请参考“封装管脚补偿”处理,在后面)

Solder Mask = Regular Pad + 0.15 mm = Regular Pad + 0.10 mm (For BGA)

Paste Mask = Regular Pad

2)Shape类型

Regular Pad = Shape大小

Solder Mask = Regular Pad

Paste Mask = Regular Pad

3、通孔类焊盘

Drill Size = Physical_Pin(参考“管脚补偿计算规则”,在后面)

Regular Pad = Drill_Size + 0.4 mm (Drill_Size < 0.8mm)

= Drill_Size + 0.6 mm ( 3 mm ≥ Drill_Size ≥ 0.8 mm )

= Drill_Size + 1 mm (Drill_Size > 3 mm )

Thermal Pad = Thermal Pad(参考“Flash计算规则”)

Anti Pad = Drill_Size + 0.8 mm

Solder Mask = Regular Pad + 0.15 mm

扫码关注

扫码关注